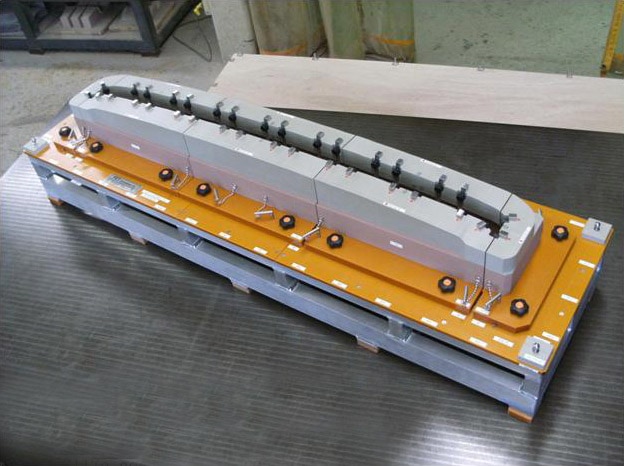

At FET Engineering, Inc., we are a progressive, intelligent provider of sophisticated jigs and fixtures for many industrial markets. Involved from the initial planning stages, we manufactured the check fixture highlighted here for a client in the automotive industry. This large scale fixture contained many complex elements for dimensional measurement of the intricate details on the lower geometry of grille radiator. Design elements included removable blocks as well as more than 30 labeled datum locations.

We milled the components from several materials, including steel, aluminum, Bakelite, and a urethane modeling material that would allow us to achieve exceptional dimensional accuracy. With extreme attention to the finest details, we assembled all of the components into a fixture with overall dimensions of 1,620 mm in length x 440 mm in width x 530 mm in height. We utilized high resolution CMM measurements to validate that we upheld the required ± 0.1 mm tolerances on the datum locations and ±.0.2 mm on the scribe lines and offset surfaces.

Within a ten week timeframe, we produced one of these fixtures with structural and dimensional integrity to last the entire 6-10 year expected lifespan of the vehicle platform. Annual calibrations ensure continued reliability.

If you are interested in learning more about this project or the processes we used to complete it, contact us directly.