We are proud to offer design and development services, partnering with customers seeking full-service engineering resources for innovative and effective tooling solutions. Our dedicated team works with you to develop and implement products and services to resolve your tooling needs. To best serve our customers, engineering support continues past production launch and remains throughout the program life.

Past Projects

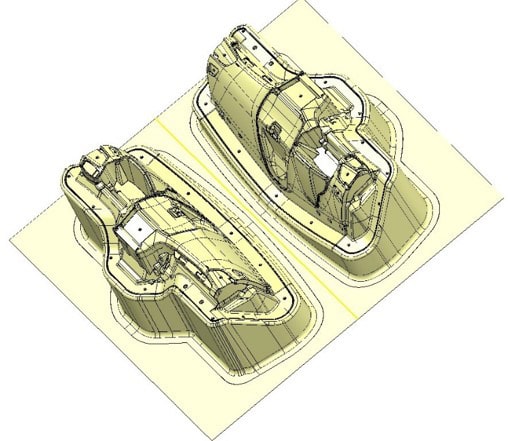

- Electroformed Nickel Slush Tool for the Automotive Industry

- In-Mold Grain Lamination (IMGL) Vacuum Form Tool for the Automotive Industry

- CNC Milling of a Grille Radiator Lower Check Fixture for the Automotive Industry