Our precision tooling solutions assist in meeting bottom line manufacturing goals of repeatability, consistency, accuracy, and cycle time reduction.

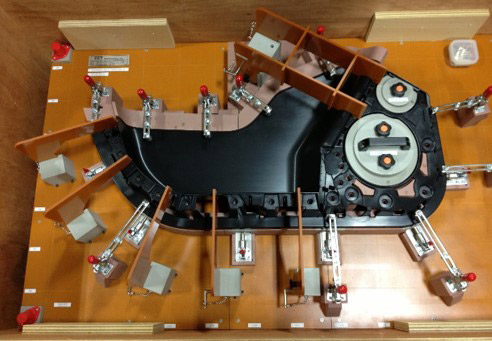

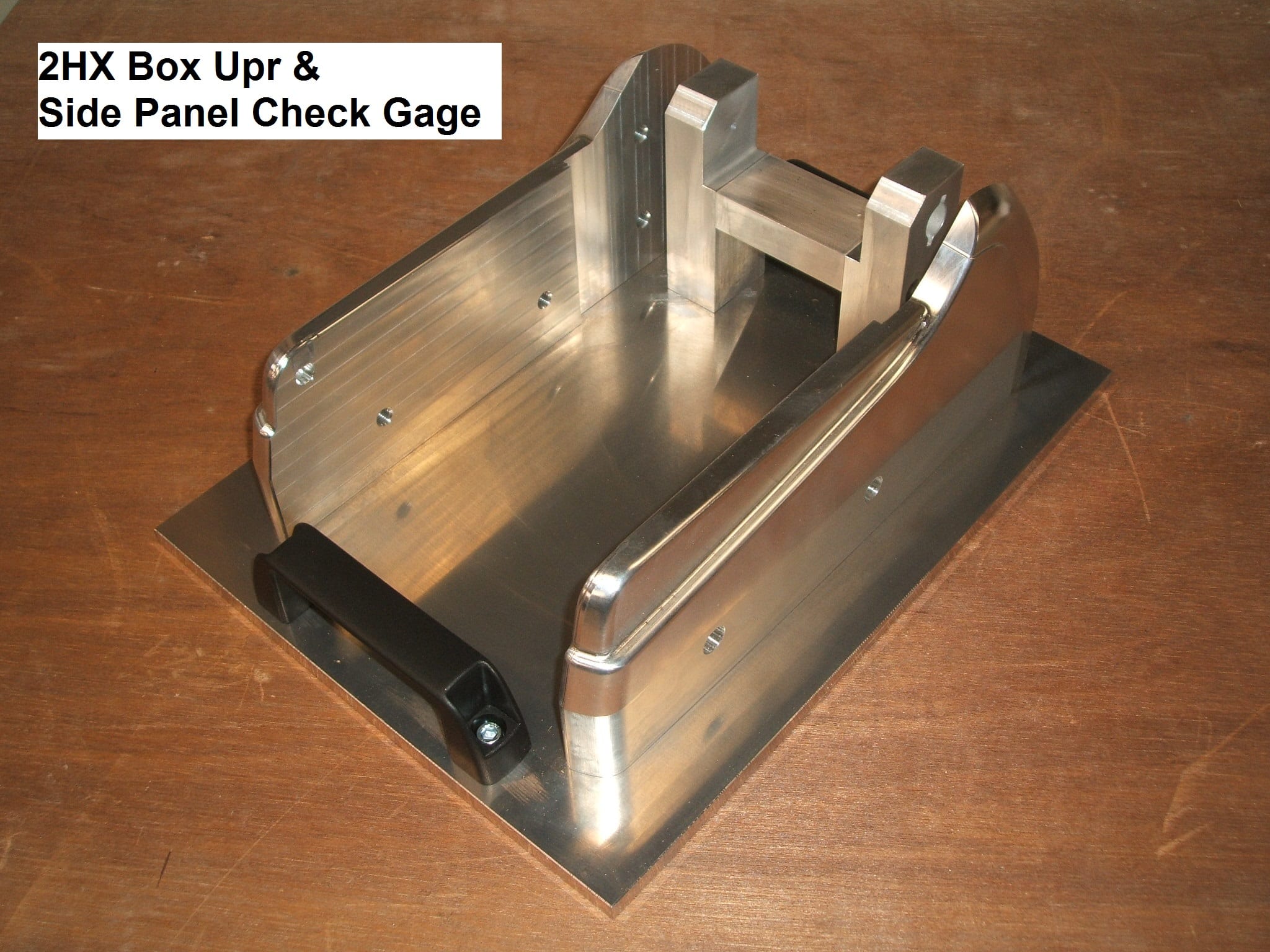

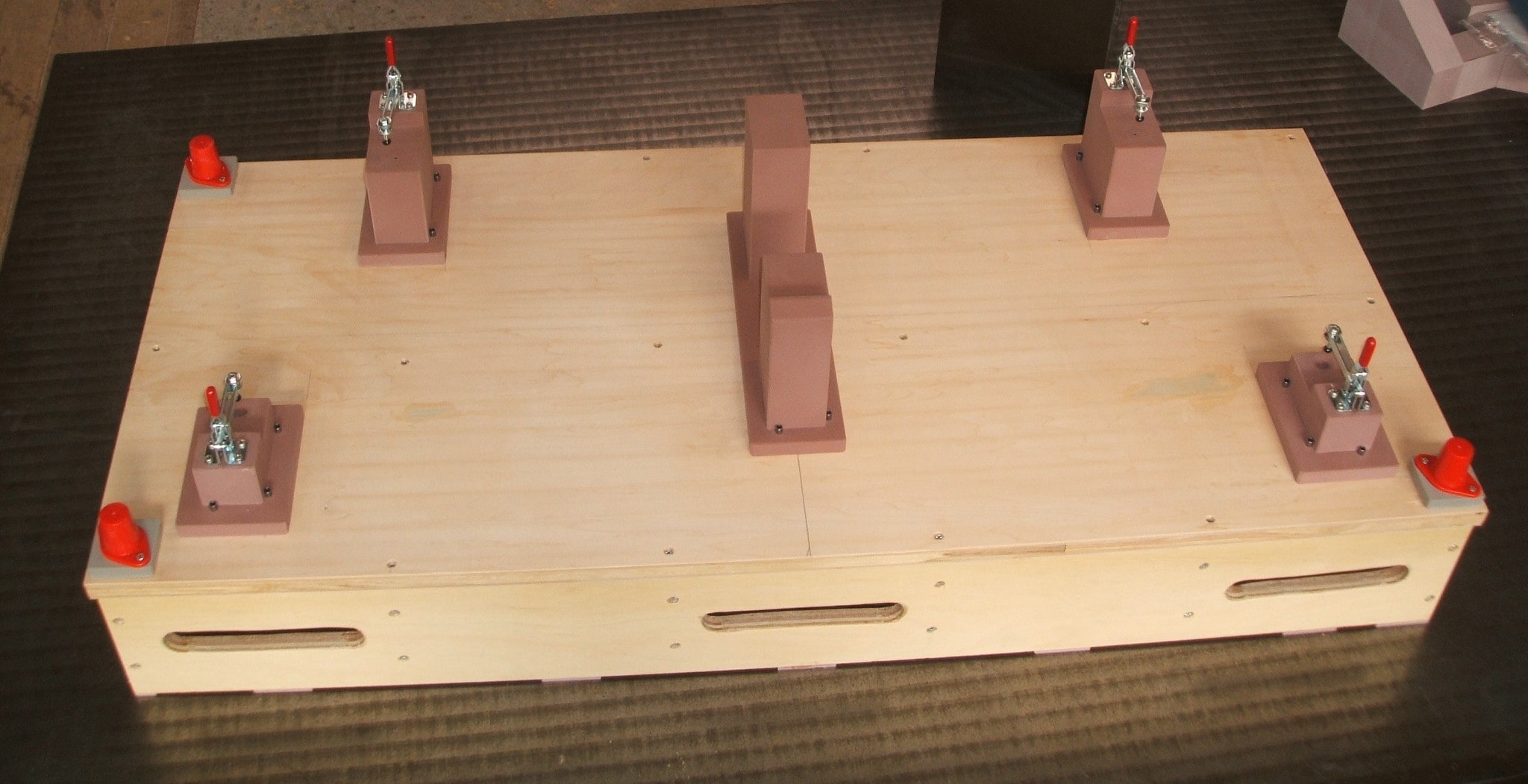

This includes complete design, engineering, modeling, manufacturing, certifications, and fixture modifications. We are also prepared to handle the implementation of engineering change instructions (ECI) for alterations in production parts. Customers across a spectrum of industries can rely on our jigs and fixtures to gauge parts, hold pieces during operation, or trim excess materials. We utilize various materials such as composites, Bakelite, resin, steel, and aluminum among other options. Gauges are furnished with certification of specified fixture tolerances by process of CMM or FARO Laser scanning.

Past Projects

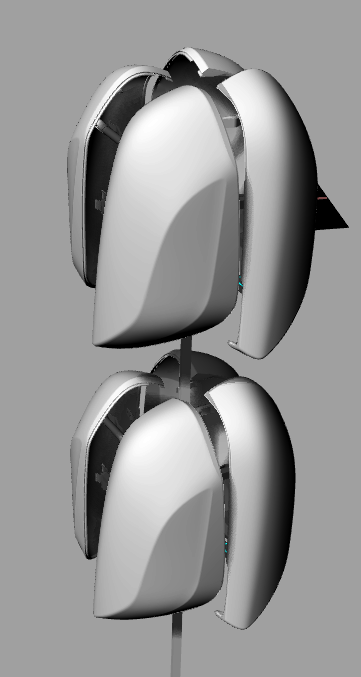

- Electroformed Nickel Slush Tool for the Automotive Industry

- In-Mold Grain Lamination (IMGL) Vacuum Form Tool for the Automotive Industry

- CNC Milling of a Grille Radiator Lower Check Fixture for the Automotive Industry