We offer high-quality custom vacuum form tooling for a wide range of applications.

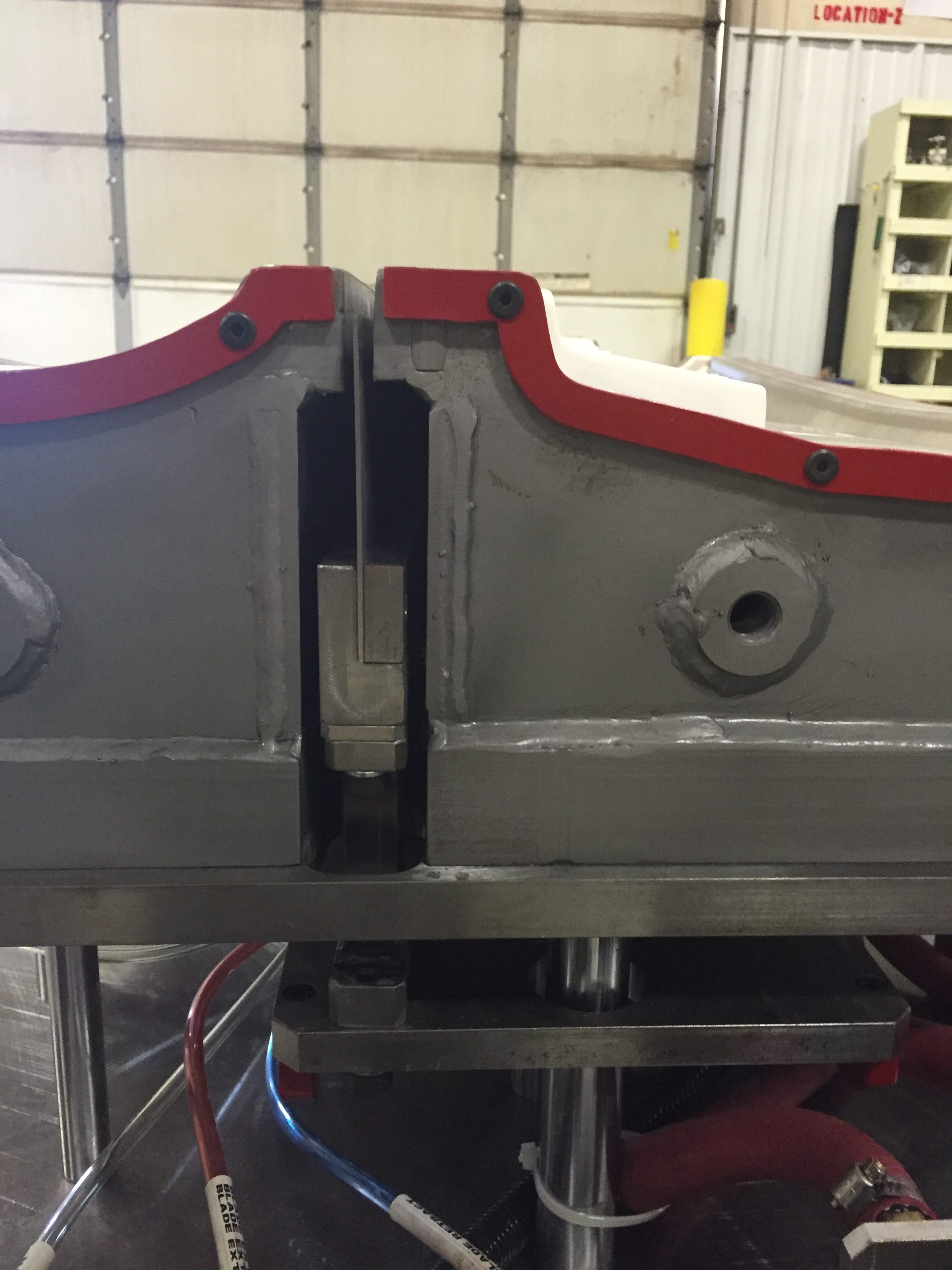

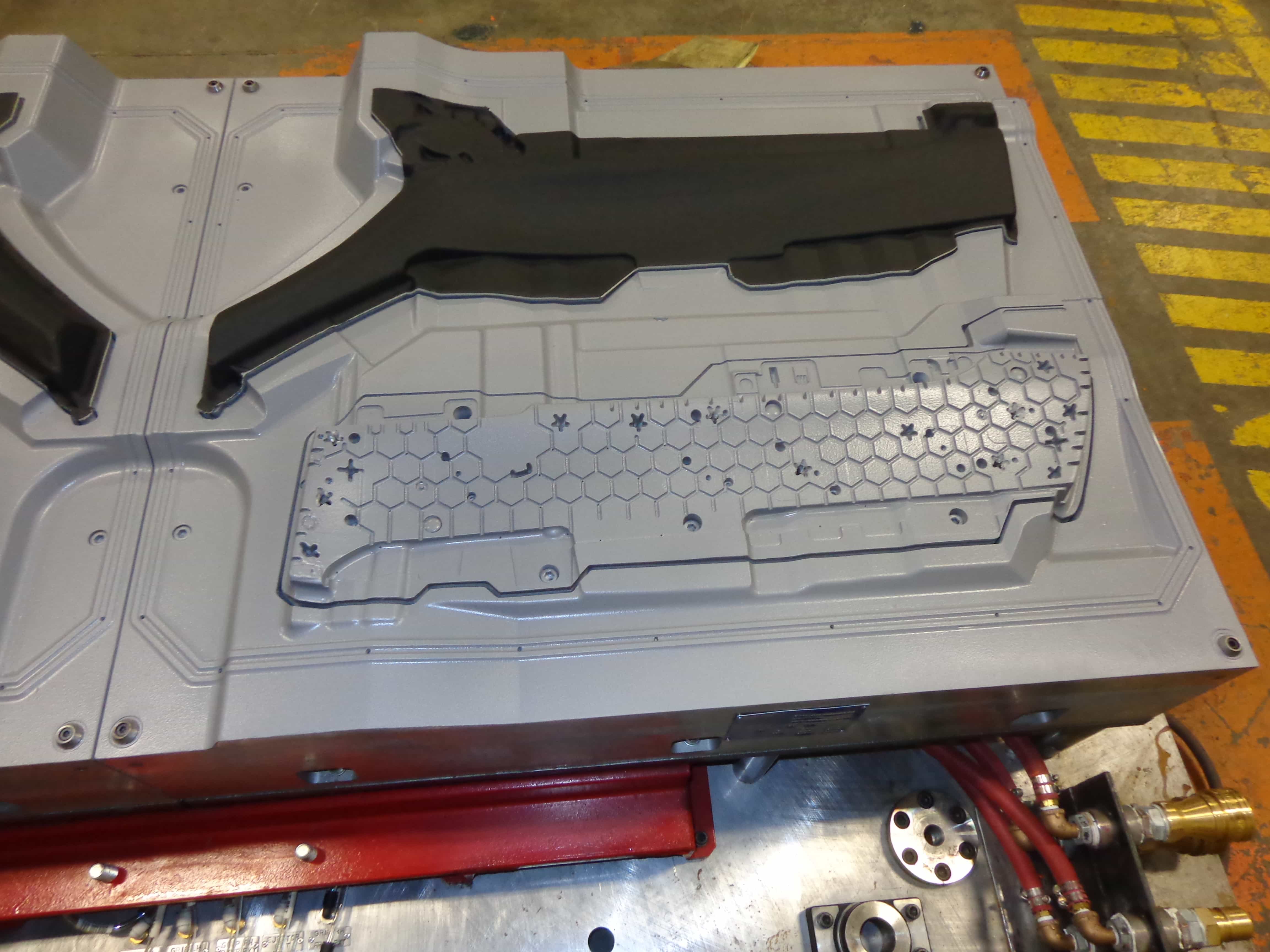

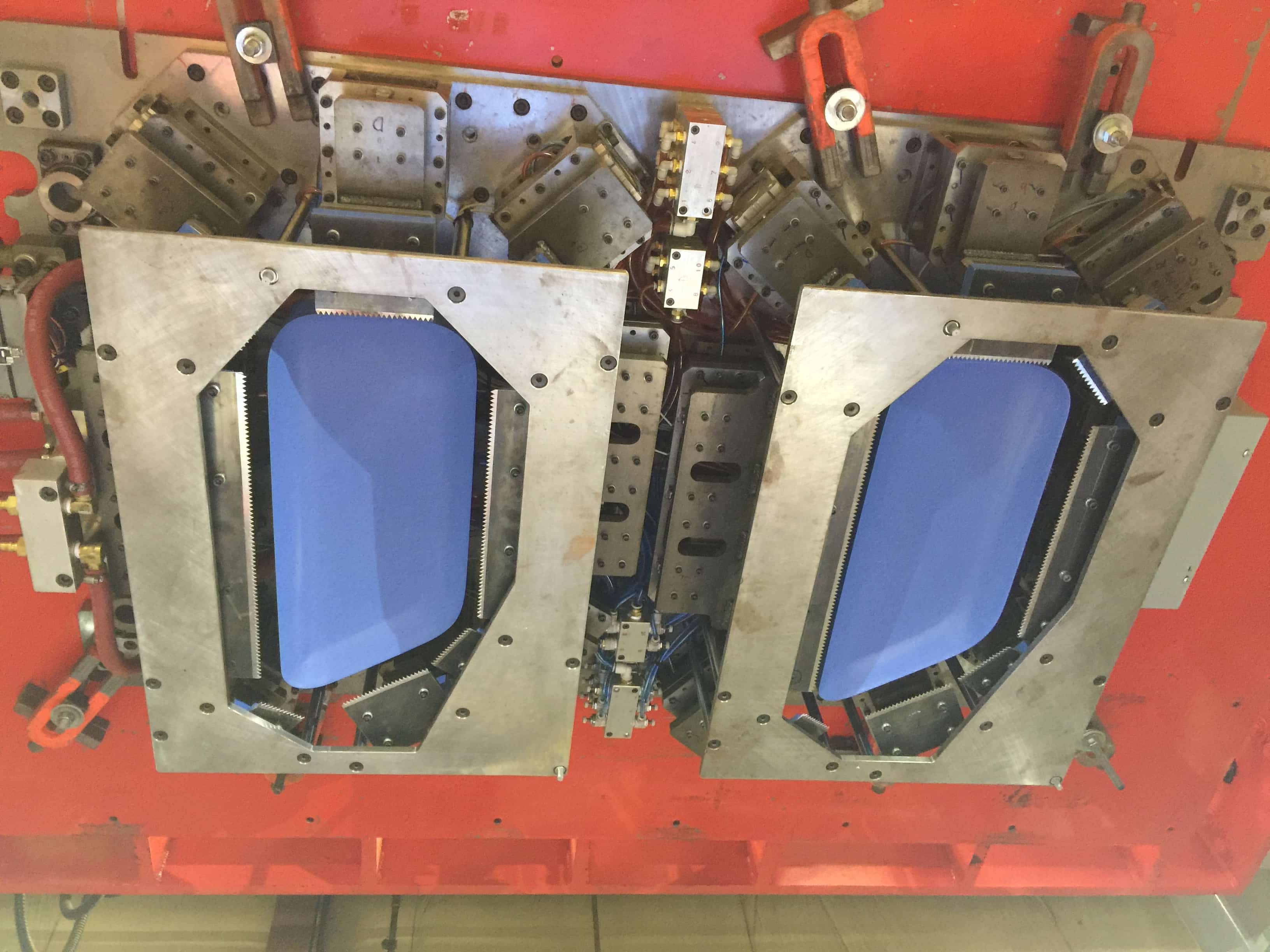

Our vacuum forming molds are expertly designed to meet the needs of our customers. With our in-house MAAC machine, trial parts can be run to assure your vacuum tool runs perfectly before it leaves our shop. We have supplied female shells, male tooling, with in-mold grain (IMG), and in-mold grain laminate (IMGL), as well as standalone and built in trim-blades.

Past Projects

- Electroformed Nickel Slush Tool for the Automotive Industry

- In-Mold Grain Lamination (IMGL) Vacuum Form Tool for the Automotive Industry

- CNC Milling of a Grille Radiator Lower Check Fixture for the Automotive Industry