The laser welding capabilities available at FET Engineering are ideal for precision repair work. We employ free hand operation methods, utilizing state of the art equipment from the Alpha Laser ALFlak series for deposit and contour welding. With welding rod diameters down to .005”, micro welding and deep channel repairs are performed with outstanding results.

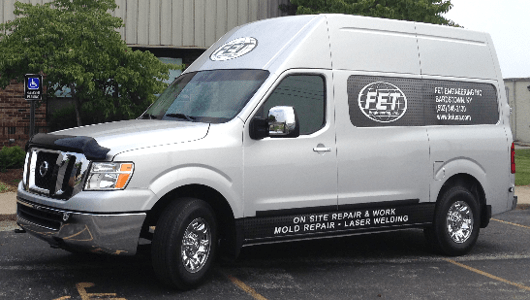

To meet a growing demand for On-Site Service, we have a Mobile Repair Unit featuring the Alpha ALM 250 laser welder.

Repairs, texture reconstruction, and countermeasures are implemented on nickel, brass, aluminum, tool steel, stainless steel, or titanium.

Advantages

High Precision in Hard-to-Reach Areas

Low Heat Input = Minimal to Zero Distortion

Rapid Turnaround

Reduce Risk to Part Bank

Minimize Secondary Finishing

Shorten Tool & Die Bench Time

Past Projects

- Electroformed Nickel Slush Tool for the Automotive Industry

- In-Mold Grain Lamination (IMGL) Vacuum Form Tool for the Automotive Industry

- CNC Milling of a Grille Radiator Lower Check Fixture for the Automotive Industry